TECHNOLOGY

standardization and specialty.

We develop innovative production technology based on our broad expertise in mechatronics, machine building and control technology. In addition, we have years of experience with various production technologies. We build robust systems that operate reliably and efficiently, taking an efficient approach to the implementation of complex industrial processes efficiently. This requires flexible application of standard concepts and components. We have therefore invested in our own standardization for hardware and software that serves as the basis for our projects. Specialist customization ensures the distinctive value of our solution and makes our platform suitable for various applications.

SMART MACHINE BASE

hardware platform for machine building.

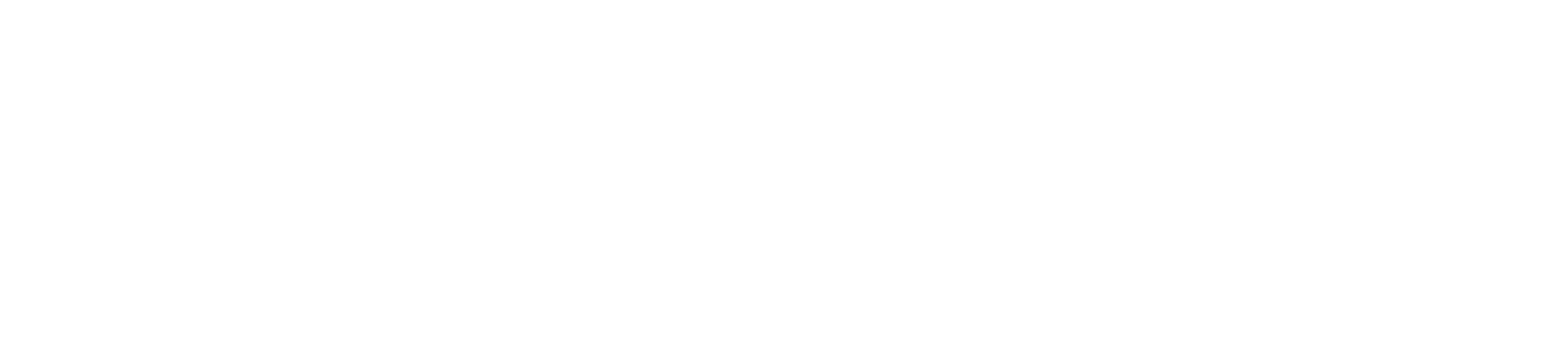

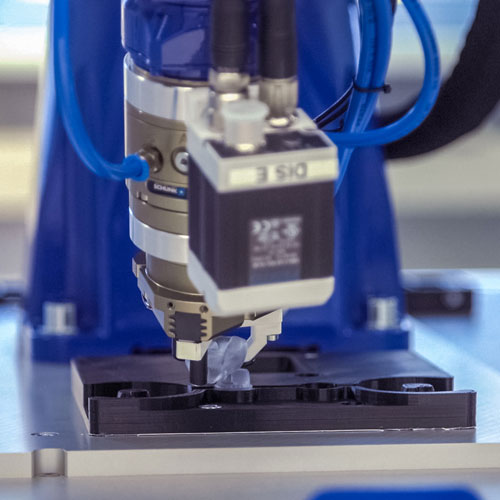

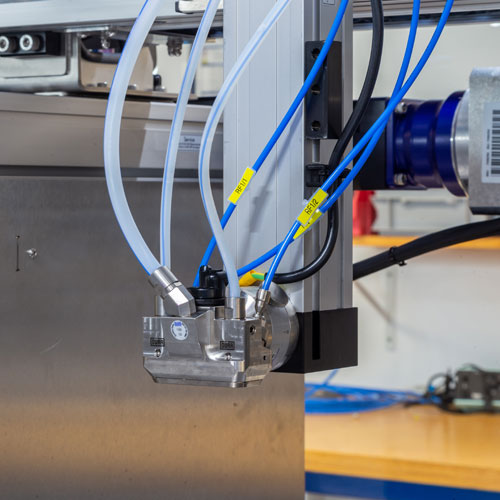

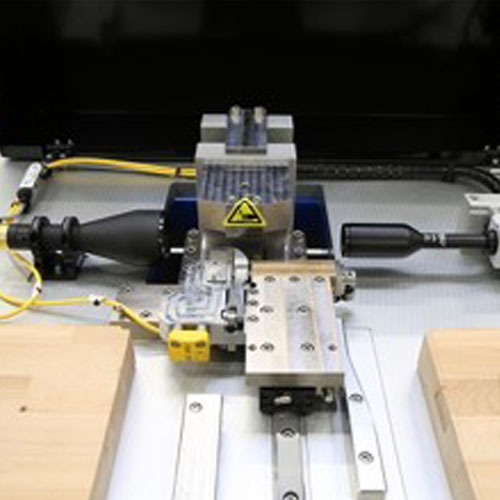

We have developed a standard machine platform with a flexible, modular architecture. This offers our customers predictable quality, manageable costs and a fast development process. In a construction with dimensions of your choice (small, medium or large), we integrate basic functionalities for the customer’s machine, such as the control cabinet with power supply, feeder and conveyor systems, compressed air conditioning and valves. Safety is guaranteed by using the right components (emergency stop, door switches) in combination with a safety PLC. We call this concept SmartMachineBase (SMB).

A mechatronic project starts with making a functional model based on S88 (ANSI/ISA-88), a standard for describing (batch) systems by means of a hierarchical structure. We then enrich the model with information about the input materials and the end product. This forms the basis for the realization, wherever possible with the configuration of standard building blocks. Examples are quality inspection modules (such as a camera and lighting), control panels (HMIs), a transport system, a manual workplace or a pick & place unit (such as a robot arm). SMBs can easily be linked together to increase capacity or physical space. This makes the concept very scalable, from pilot-line to fully automatic solution.

Finally, we add tailormade customization to the standard: functionality that we integrate or develop specifically for the unique customer process. All this makes our SMB suitable for various applications and efficient system development. Because the basic functionalities have already been worked out thanks to standardization, we offer manageable costs, predictable quality and a fast development process to the customer. This allows us to focus in development on what is truly innovative and distinctive for their production success.

BRIX

software platform for machine control.

We prefer to use Beckhoff Automation technology to control production machines, in combination with our own control platform (BRIX). This framework has the same S88 basis that we use for the SMB and is also based on the PackML standard. The name BRIX refers to multifunctionally (X) deployable building blocks (‘bricks’). We apply this control concept to both SMB-based machines and other systems. BRIX provides us with great flexibility, especially thanks to the free configurability of many controllable standard hardware items, such as motors for motion axles, sensors and valves.

BRIX provides a standard Graphical User Interface (GUI) for the user control panel. In addition, there is a database link and communication to control at higher levels (e.g. MES, ERP, Scada, Cloud). Links with other IoT systems (Internet of Things) and the Fiware platform, for example, are possible by default. From there, it is a small step to our own digital twin, which our customer can use for simulating and monitoring their system. The use of artificial intelligence can then contribute to smarter use of data and further optimization of production. For this, we also have the necessary expertise in-house and we are happy to be a partner for the customer.